3D Printing

Printers are the bane of human existence! Even now, as I am typing this, the office printer at my workplace is jammed. For every presentation or lesson, there has been a printer jam. Well, if there is one thing that is sure to alleviate all the problems of printing, it has got to be the addition of a third dimension! 3D printing is not really new, but it is certainly more accessible than it used to be. You can go to amazon right now and buy an Ender 3D printer for about $100. There are many different styles of 3D printing as well. The most popular printing methods available to consumers for purchase are filament printers and resin printers.

Filament 3D Printers (FDM)

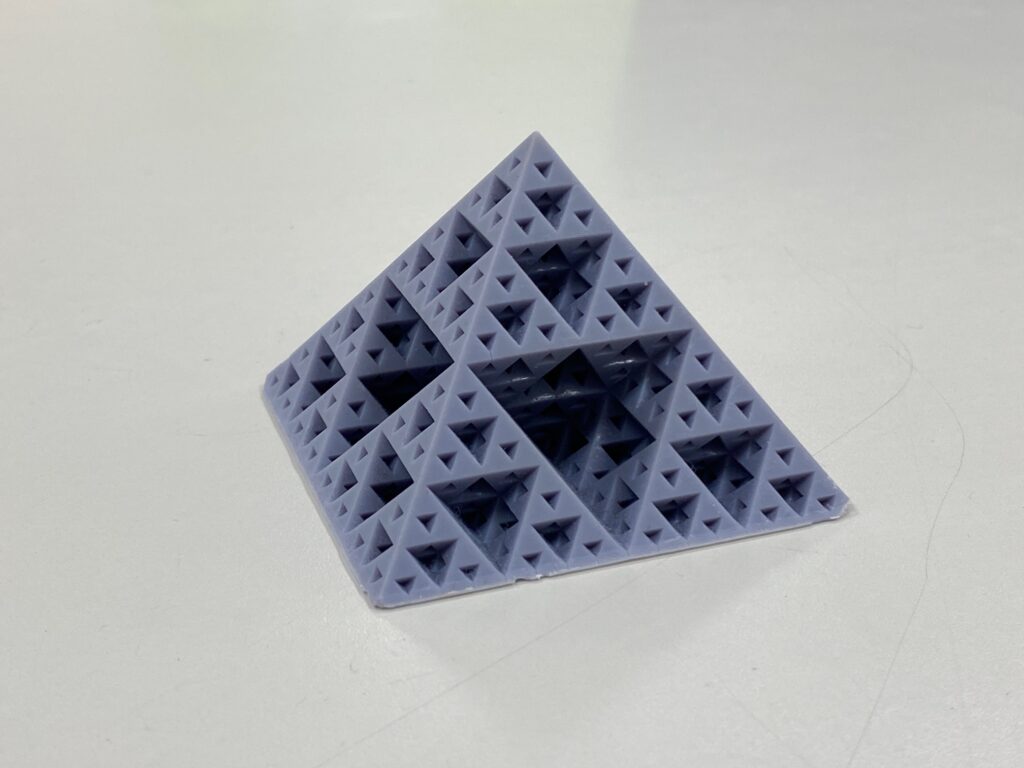

To start off our deep dive of 3d printers, lets’ start with Filament printing. Filament printers use rolls of filament, which can be one of several varieties of plastic. These rolls come in many colors and materials. The printer has a “hot end” that heats up the filament as it passes through the extruder, similar to how a hot glue gun works. As the filament is pushed through the extruder tip, it is deposited on a build plate. The extruder and build plate move in 3 dimensions as the item is printed out.

Pros

- Many colors and materials to choose from, and swapping filaments is generally an easy task.

- Quickly remove the finished print from the bed with no post processing.

Cons

- Rougher lines on the finished prints. Postprocessing required to smooth out surfaces for a more finished look.

- Filament can get stuck on the inside on the extruder and create a filament jam. Depending on your printer, repairing this could mean sending your extruder in for service, or taking it apart yourself.

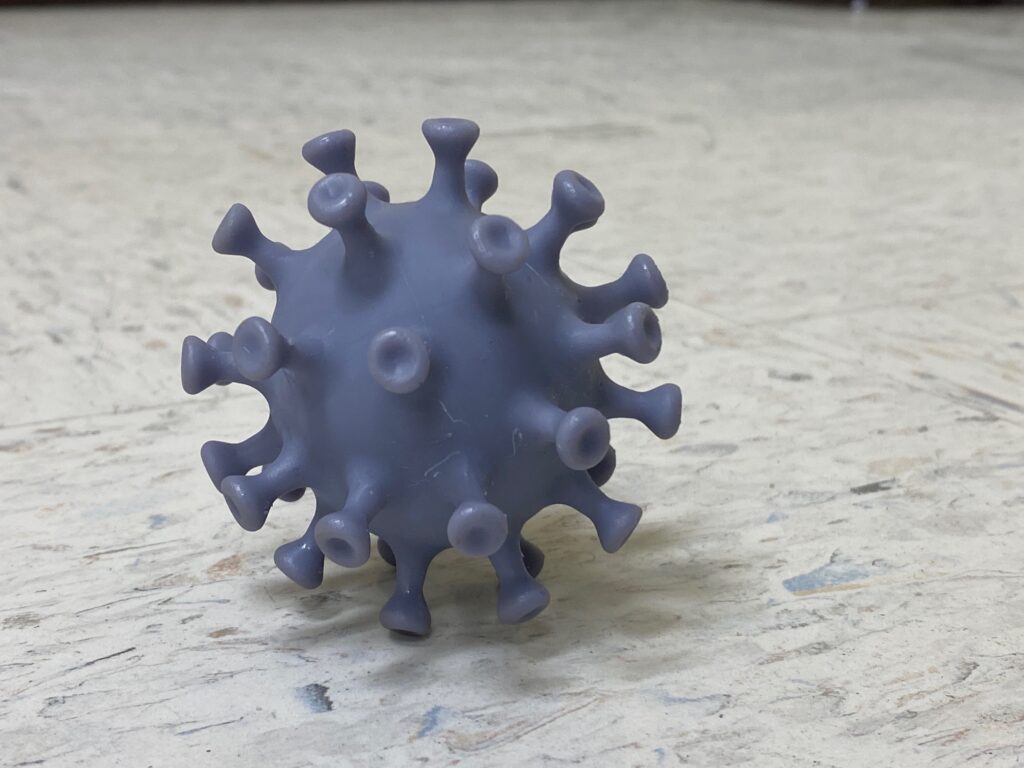

Resin 3D Printers

Resin printers have a vat that holds different types and colors of UV activated resin. A build plate is lowered into the resin and it rests just above the bottom of the vat. An LCD screen that sits just below the clear bottom of the resin vat displays the first layer of the print. This allows the UV light to pass through only the portions of the LCD that are not blocked off by the LCD display. The resin hardens in an exact shape of what is on the screen.

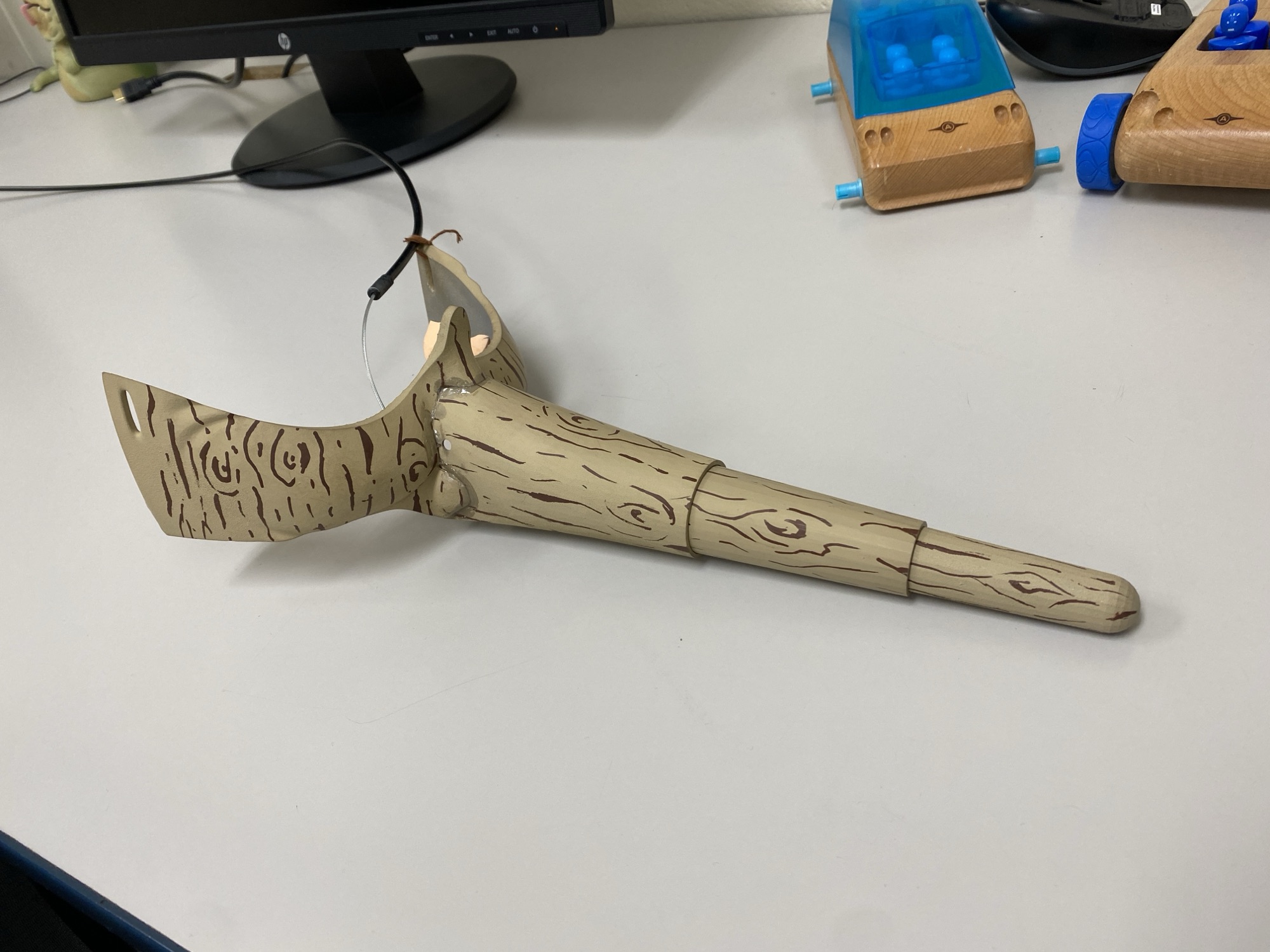

As the printer builds the object, the build plate is then raised to break the print away from the bottom of the vat, which is a layer of FEP material that lets go of the cured resin, but allows it to stick to the build plate. This allows fresh resin to fill in the gap and be ready for the next layer. This process repeats until the object is printed. The part is then removed from the build plate and cleaned with alcohol, or another cleaning agent. Once the object is fully dried, it is sent to a curing station (or laid out in the sunlight) for a final cure to set the resin permanently. I am currently using a Elegoo Mars 3 Ultra resin printer for all of my printing at home.

Pros

- The print resolution is much higher, which makes the object look much higher in quality.

- Multiple parts do not increase print time. Time is only affected by hot many layers high the print file is.

Cons

- Prints seem to be more brittle, especially with the standard UV resin. Depending on your application, you may have to shell out more for a more flexible resin.

- After printing, the print requires postprocessing such as cleaning and curing.

- Resin is toxic before curing. HANDLE WITH GREAT CARE! Respect the resin.